cheap etching machine for small pcb’s

I quit my last job where I had access to great labs – including the one for making PCBs the easy way (yeah, they have all the nice/expensive tools from Bungard … and a CNC miller/cutter). So now I had to decide how to setup the needed infrastructure for making PCBs@home. Here are some of the results.

For putting the layout on the PCB I decided to use the direct toner transfer method with a modified laminator like described here. Cause of the chicken-and-egg-problem I used an Arduino to control the heater instead of a dedicated board (what I create after the setup for making PCBs is done so I can create more boards…). It works very well – thanks to all the folks that invented/improved that technology.

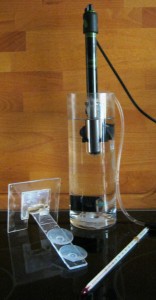

Since I do all the fun at home I choose sodium per sulfate as etchant – its a clean and safe solution. First I thought about buying a commercial etching machine. But after some reading it turns out that all the inexpensive and/or cheap machines are … to expensive. I moved to the hardware store and got all I needed for less then 50 euro:

- round glass vase, 25 cm hight, 9 cm diameter ~ 5 €

- aquarium heater, 100 W – 20 €

- aquarium membrane air pump ~ 10 €

- fizzy stone ~ 2 €

- 2 m silicone tube ~ 2 €

- return valve ~ 3 €

- a sheet of 4 mm acrylic glass (30 cm x 20 cm) ~ 5 €

- pack of 4 cupping vessels ~ 2 €

I also ordered a 24 cm long tee thermometer that goes till 110 degree Celsius for ~8 €. But a simple 2-euro window thermometer with a range from -x..50 degree Celsius also does that job. But the tee thermometer looks better. Much!

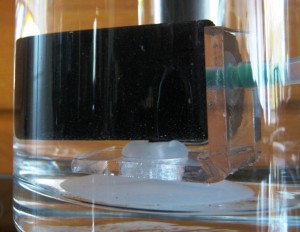

First I created an holder for the fizzy stone by heating a small strip (5 cm x 10 cm) of the acrylic glass with my kitchen gas torch in the middle and bend it by 90 degrees. Two holes later a cupping vessel and the stone are mounted and put in place on the ground of the vase:

Cause of the air bubbles the etchant could spray out of the upper end. A quadratic cover of 10×10 cm acrylic glass makes a good seal. To keep it in place I glued a smaller piece (5.5×5.5 cm) that fits (nearly) the inner diameter of the glass vase in the center of the larger one. The width of hole for the heater is aligned to the diameter of his glass rod so the little bigger head could keep down the top plate. The tee thermometer is plugged through a 8 mm hole and fixed by a rubber band.

The PCB holder is made from a strip of the acrylic glass and two cupping vessels so only one-sided PCBs are possible for now. In a first run I mold the top cover and the PCB holder together by heating the ends and the plate with a gas torch. It holds bombproof till I tried to fix the angle of the holder a little by heating the junction again. After cooling down it breaks of – I think the heat applied to much stress to the material. A little of cyan acrylic glue fixed that mistake. Lesson learned: Don’t mold. Just glue!

I had to remove the mechanical temperature limiter to get the needed 45..50 degree Celsius for the etchant. I simply used a rasp for this purpose. A first test with 1 liter of water shows that the machine needs ~25 minutes to heat up from 16 to 48 degree.The hysteresis of the mechanical temperature switch is 6 degree so the etchant cools down till 42 degrees – 3 degree below optimum. But cooling down takes that long that I could etch one PCB inside the temperature frame between 48 and 45 degree. For now that fits my needs (I do not plan to go into mass production).

Finally I filled in the etchant: 200 gram sodium per sulfate and 900 ml water. The finished etching machine looks not so bad:

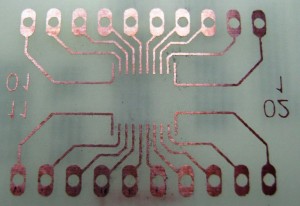

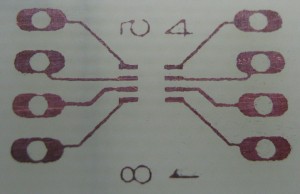

A first run of the complete setup produces great results. Etching of the complete board takes ~10 minutes. The area of the PCB that was in the stream of the air bubbles was ready after 7 minutes. 3 minutes more for the rest – no under-etching at all. Some samples below…

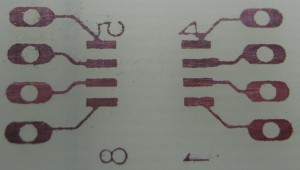

And finally the one I’m most happy with (cause it shows that even that small structures are not the limit):

And yes, the numbers are not mirrored. Two bad things about glass vase: due to the small diameter the size of the PCBs is limited to ~8 cm on one side. The second is about filling the etchant from the vase into a bottle. It wont work very well. The vase has a cutted border so some of the liquid „hangs“ on the glass and flows down of the outside of the vase. But after that great success I ordered a bigger glass vase with a diameter of ~11 cm and a border that is round molten. I think version 0.2 will solve that problems.